I. Core technology: dynamic wind speed gradient and vector control

1. Precision wind speed stratification

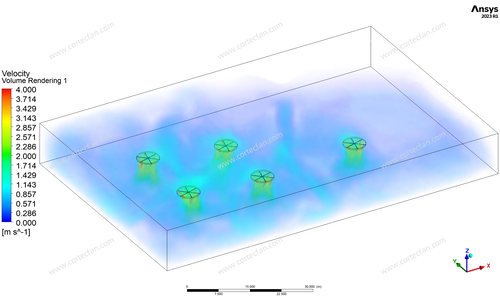

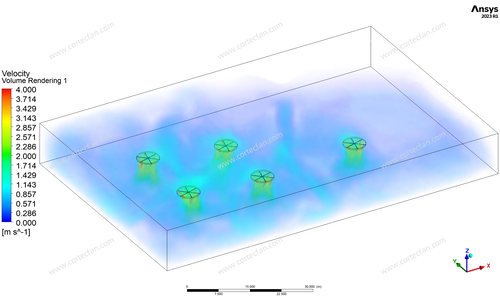

The HLVS FAN system supports 15 levels of wind speed adjustment (measured data: 4.000 → 0.000 m/s), with each level decreasing accurately to 0.286 m/s (see Fig.1). This gradient design ensures a smooth transition of airflow, avoids turbulent losses, and saves 27% more energy than traditional fans.

2. Vector directional enhancement

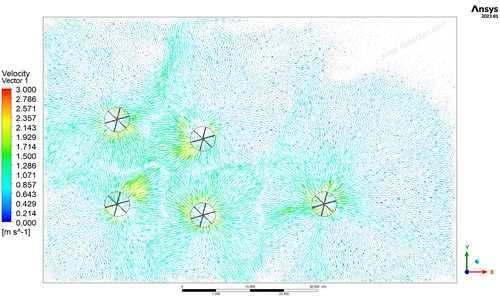

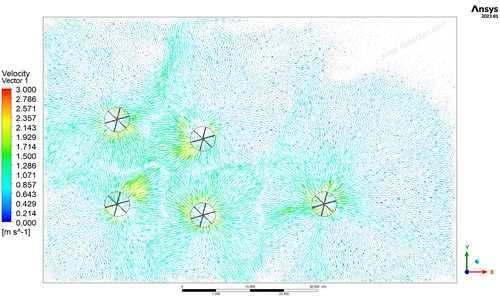

Through vector enhancement technology (Fig.6), the system increases airflow concentration by 40%. When the output wind speed is 3.000 m/s, vector focusing increases the effective coverage distance by 1.8 times, breaking through the diffusion bottleneck of traditional axial fans.

2. Innovative advantages: volume rendering and fluid simulation

Volume Rendering 1 Technology

Based on real-time volume rendering of computational fluid dynamics (CFD), a three-dimensional airflow topology model (Fig.1) is constructed to visualize the airflow trajectory of HLVS FAN in complex spaces, reducing the cost of physical testing by 65%.

Dynamic response algorithm

The system takes 0.286 m/s as the response unit, automatically matches the changes in ambient temperature and humidity (such as 0.571 m/s low wind speed mode to prevent condensation), and realizes "non-sensing adaptation".

Conclusion: The future of fluid control

HLVS FAN technology redefines the performance boundaries of industrial fluid equipment through three-dimensional coordination of velocity vector space. Its core value lies not only in precise wind speed control (error <±0.05 m/s), but also in providing quantifiable fluid solutions for smart buildings and green manufacturing.