CorTec industrial evaporative air conditioner use Cold water to cool the condenser, which make the air conditioner has higher EER than traditional AC, bigger air flow, quicker to cool, saving energy 40%-60% .

TECHNICAL PARAMETER

PRODUCT DESCRIPTION

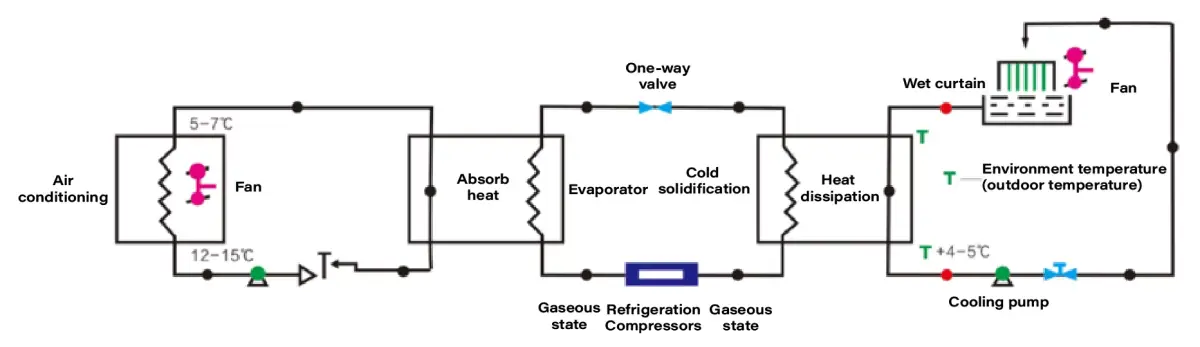

The CorTec air conditioning system has a built-in heat-absorbing medium - refrigerant. The refrigerant generates pressure through the operation of the compressor. It is throttled by the expansion valve and passes through the evaporator inside the unit. The indoor fan blows the air indoors and absorbs the indoor air. The heat in the air and the refrigerant return to the suction end of the compressor through the pipeline. Through the compression of the compressor, the temperature of the refrigerant is increased. After passing through the wet curtain radiator of the outdoor unit, the refrigerant is converted from a vaporized state to a liquefied state. During the conversion process, a large amount of heat is released, and the heat is removed through the outdoor unit fan. Through repeated cycles, the purpose of rapid cooling is achieved, thereby quickly cooling the indoor environment. Water-cooled condensation reduces the evaporation pressure of the system and the exhaust pressure of the compressor, allowing the compressor to achieve a higher energy efficiency ratio and minimizing the input power of the compressor.

The water-cooled condensing temperature of traditional air conditioners is 56°C. In the harshest environments, evaporative air-conditioning units can also reduce the water-cooled condensing temperature to below 35 degrees. In the process of the heat exchange system, cooling is directly obtained close to the wet curtain temperature. water temperature, improve the energy efficiency ratio of the air conditioner, achieve energy saving effect, and the unit has no heat source to discharge, and will not cause pollution to the environment. After years of research and testing, CorTec's energy-saving air conditioners adopt Swedish CEID evaporative cooling technology, combined with many of CorTec's own technology patents, and multiple technical supports to accelerate the heat dissipation system of energy-saving air conditioners. Cooling, the energy efficiency COP during refrigeration is as high as 5.1, and the overall energy consumption is saved by 40%-50%.

| Ventilation type | Traditional separate air conditioner | Central air conditioner | Air coolers | CorTec Water-cooled evaporative air conditioner |

| Electric consumption/H | 48KWH | 45KWH | 16KHW | 20KWH |

| Outdoor temperature 36° | Indoor 26° | Indoor 26° | Indoor 32° | Indoor 26° |

| Investment capital cost | Nearly 20000USD | Nearly 40000USD | Nearly 8500USD | Nearly 13000USD |

| Installation way | Copper tube Connection | Ceiling installation | Wall installation | Water tube connection |

| Advantages & disadvantages | Each air conditioner is controlled separately, area coverage small, cooling efficiency. | Cooling efficiency is good, but cannot be controlled separately, investment cost is high | The air cooler cools quickly and consumes relatively low energy. However, the cooling effect is limited by the outdoor temperature and humidity. The cooling effect is poor in high temperatures and humid weather, and the installation cost is relatively expensive. | Cooling efficiency is good, large coverage area, can be controlled separately, comparatively low investment cost, but requires a requirement on water quality. |